The computerization of data in recent decades has allowed many industries to study the performance of their systems to optimize their operation and react quickly in the event of a failure. Unlike industries such as aeronautics and automotive, the plumbing industry, more specifically that of backflow prevention systems, has remained faithful to older and proven mechanical technologies. However, some manufacturers have recently put on the market intelligent reduced pressure backflow prevention devices (RP) whose usefulness will be discussed in this article.

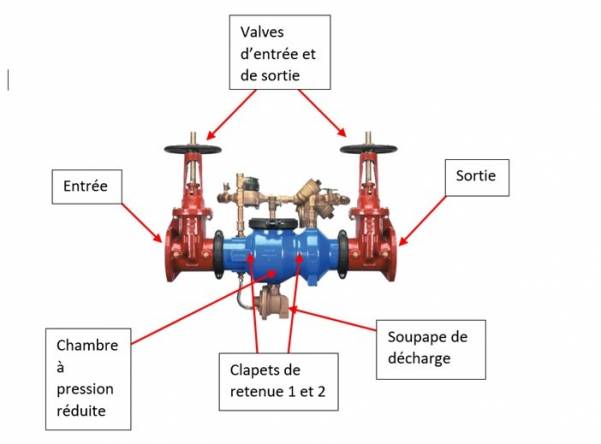

It is important to know the operation of a reduced pressure backflow prevention device (RP) to understand the usefulness of the proposed systems.

When a RP operates normally, the pressure inside each of its sections is equal and constant. In the event of siphoning or back pressure, the two check valves will close to protect the drinking water system. Then, the relief valve would open to evacuate the water and restore a uniform pressure in the device.

In the event that the device is defective, the relief valve could remain open and leak profusely. This could cause significant damage if the water supply is not turned off. The main function of the systems offered by the manufacturers is to send an alert via internet or cellular network to the maintenance staff responsible of the water infrastructure when the relief valve opens for an unusual delay. Simultaneously, another signal is sent to an intelligent supply valve located upstream of the device in order to cut off the water supply and thus stop the water discharge.

Even if at first glance these systems seem very useful, they still have certain particularities that may make them less interesting in the eyes of some users:

- Unlike a mechanical device, the intelligent functions of the new systems make them much more expensive than a conventional system.

- Powering the smart functions requires that a power supply be located near the place of installation of the smart device. This can sometimes be difficult, especially if the installation of the device had not been planned in the layout of the installation site.

- The new functionalities of smart devices require additional training of the technicians in charge of their installations as well as the maintenance staff who will use them on a daily basis. This not only generates costs but does not guarantee that all employees will be receptive to the idea of changing from a simple mechanical system to a system that may seem more complex at first glance.

Considering all these characteristics, smart devices are, however, recommendable for certain specific applications. In the event that these are installed in unfrequented mechanical rooms in buildings with a critical vocation, they can be a very interesting asset.

For example, a building housing computer servers could greatly benefit from this type of system considering that water damage could be catastrophic for all users of the servers. Also, in the event where the device installation room is located at the top of a multi-storey building, the installation of a smart device could prevent substantial water damage. However, in the case of a busy plant, where the water spill would not have significant impacts on production or facilities, it would be excessive to install a smart device.

Properly assessing the probability that a spill from the relief valve could occur and above all identifying the potential impacts that water damage would have will determine if a smart device could be an interesting tool.

Sources:

- Pmmag. New technologies in backflow prevention – Flood protection and testing. https://www.pmmag.com/articles/102851-new-technologies-in-backflow-prevention-flood-protection-and-testing

- Plumbing and HVAC. Connected backflow prevention. https://plumbingandhvac.ca/connected-backflow-prevention/

- Watts. Flood Protection Backflow System. https://www.watts.com/floodprotectionsystem

- Zurn. Connected Backflow. https://www.zurn.com/innovation-efficiency/plumbsmart/connected-backflow-preventers