Our achievements

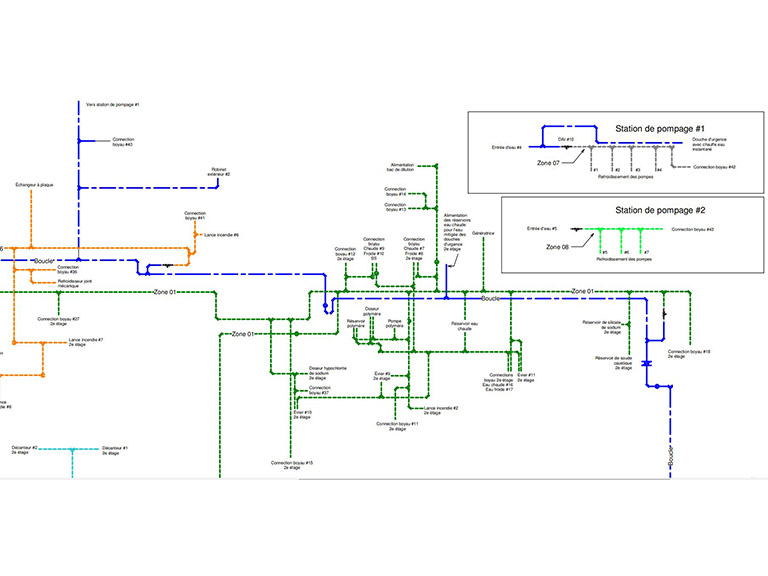

Our achievements are varied and always according to the specific needs of our customers and respecting pre-established budgets. We have carried out various projects, of different sizes and complexity, in the upgrading of the

- main water inlets to the building,

- emergency showers,

- cross-connections,

- drinking water distribution networks,

- booster pumps,

- And others

We are involved in various phases depending on the mandates granted, either for:

- technical consultation,

- engineering analysis,

- network characterization,

- the design of plans and specifications (based on 3D scanning and modeling),

- supervision and management of the work,

- the development of an action plan,

- the implementation of a maintenance protocol,

- personalized training,

- etc…

Food Processing Plants | Pharmaceuticals, Laboratories and Research Centers | Chemical Plants | Pulp and Paper Mills | Data Centers and Telecom | Manufacturing and Storage Companies | Shopping Centers | Office buildings | Hospitals and Clinics | Universities and Schools | Municipalities and Government Buildings | Residential Buildings

Food Processing Plants

Pharmaceuticals, Laboratories and Research Centers

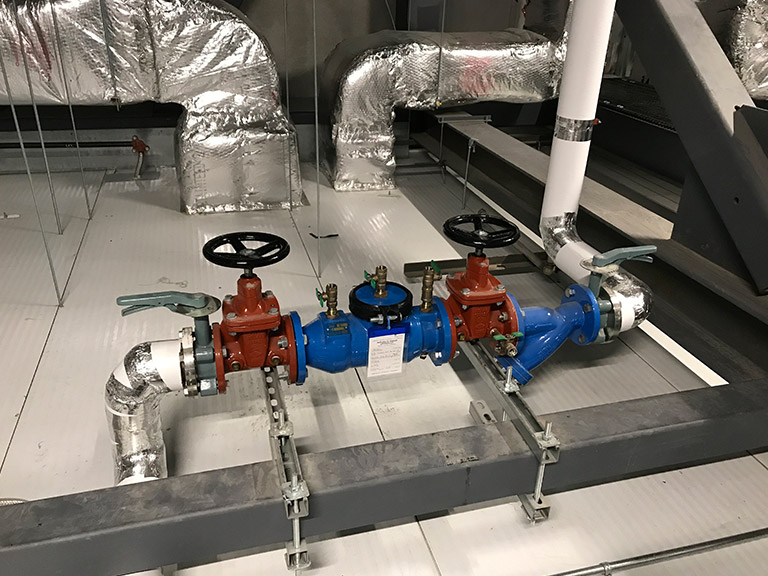

Work completing in 24 hours with an alternative supply through the fire water inlet. Carried out water quality testing with no impact on operations.

Technical challenges: 6-inch water inlet in a limited workspace requiring a short-term shutdown so as not to interfere with research activities.

Pharmaceuticals, Laboratories and Research Centers (continued)

Engineering analysis, field testing and elaboration of an action plan to correct non-conformities as well as the implementation of a maintenance protocol for a network of 50 emergency showers in a research laboratory.

The challenges are numerous such as the presence of colored water, very variable temperature, inconsistent pressure and flow, non-existent floor drain for deluge showers, defective and poorly adjusted showers.

Chemical Plants

Chemical Plants (continued)

Pulp and Paper Mills

Data Centers and Telecom

Manufacturing and Storage Companies

Heavy Industry

Shopping Centers

Office Buildings

Hospitals and Clinics

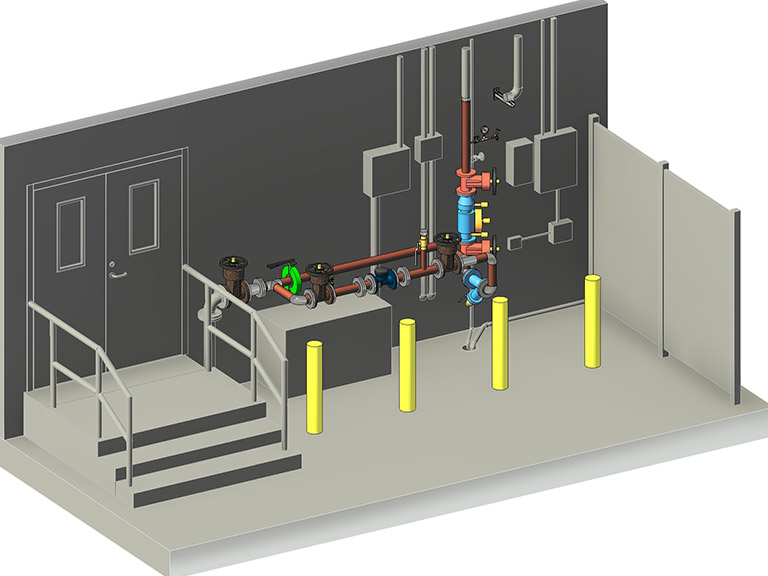

Complete engineering mandate with an outage and a installation in 8 hours which is done without change request and without major interruption of service.

Many challenges :

- Implementation of 2 backup plans to ensure a constant supply to the building,

- Non-existent initial infrastructure plans,

- Dismantling of several unused equipment requiring several surveys.

Universities and Schools

Work on the main water inlet of the university and on the pipes in the mechanical room with 4 sub-projects, without any request for addition or addendum, which lasted 6 hours with validation of the operating parameters of the booster pumps.

Technical details:

- Implementation of 2 backup plans to ensure a constant supply to the building,

- Non-existent initial infrastructure plans,

- Necessary rearrangement in limited working space.

Municipalities and Government Buildings

Municipalities and Government Buildings (continued)